TOP > MANAGEMENT SYSTEM > TOTAL SOLUTION

High Value Added From Technical Services.

Technical Proposal

We propose appropriate catalyst systems for customer’s units, and provide technical service contributing to the optimization of operation.

Performance Projection

We propose the most appropriate catalyst system for customer’s unit with our system optimization model (Loading Diagram Optimization model), and estimate product properties and catalyst performance with hydroprocessing estimation model.

Reactor loading & Start up

We recommend the loading procedure to increase the contact efficiency of reactant fluids and catalyst.

We recommend the presulfiding procedure to obtain expected performance, preventing the activity loss caused by hydrogen reduction of the active metals or coking.

Operation Monitoring

We provide the monitoring report about the operation in the customer’s unit.

We propose optimization of the operation conditions and estimate the catalyst life.

Troubleshooting

Our technical staff supports the customers when any issue or question is developed about the operation conditions or catalyst performance.

» Examples

- Elimination of sulfur recombination in Naphtha Hydrodesulfurization units

- Specifying the cause of product color deterioration in sulfur free diesel production, which is caused by the leakage of feed to product oil in the heat exchanger

- Proposal of relaxing the delta pressure build-up in reactors

- Improvement of gas and liquid distribution by the renewal of reactor internal

Reuse of regenerated / rejuvenated spent catalyst

Reuse of spent catalyst by regeneration and rejuvenation contributes to the preservation of global environment through the reduction of industrial waste and energy consumption. Adoption of offsite regeneration has been increasing as a remarkable service for cost reduction in not only refining but also for petrochemical catalysts. We provide technical support for catalyst loading, startup, etc. When regenerated and rejuvenated catalysts are combined with fresh hydrotreating catalysts, just as we do for complete loads of Ketjenfine catalysts.

» Offsite Regeneration

We provide high quality of offsite regeneration service with superior regeneration technology licensed by Eurecat France S.A..

» Offsite Rejuvenation Process (REACT)

We provide REACT processing service to rejuvenate regenerated STARS catalyst and to recover the activity to almost same as fresh catalyst. REACT technology was developed and patented by Nippon Ketjen and Albemarle.

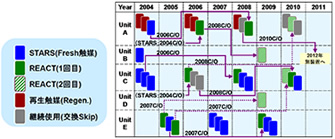

Cascade use of catalysts at refineries

- A large amount of cost reduction is possible by cascade use of catalysts between units or refineries.

- An example of cascade use is shown in the right figure. Circa 35% reduction of catalyst costs and a reduction of circa 60% of fresh catalysts are achieved in this example.

We undertake collaborative catalyst development and commissioned catalyst manufacturing based on recipies provided.