TOP > PRODUCTS & SERVICES > OFF-SITE REGENERATION / REJUVENATION SERVICE

Reuse of regenerated / rejuvenated spent catalyst

Reuse of spent catalyst by regeneration and rejuvenation contributes to the preservation of global environment through the reduction of industrial waste and energy consumption. Adoption of offsite regeneration has been increasing as a remarkable service for cost reduction in not only refining but also for petrochemical catalysts. We provide technical support for catalyst loading, startup, etc. When regenerated and rejuvenated catalysts are combined with fresh hydrotreating catalysts, just as we do for complete loads of Ketjenfine catalysts.

» Offsite Regeneration

We provide high quality of offsite regeneration service with superior regeneration technology licensed by Eurecat France S.A..

» Offsite Rejuvenation Process (REACT)

We provide REACT processing service to rejuvenate regenerated STARS catalyst and to recover the activity to almost same as fresh catalyst. REACT technology was developed and patented by Nippon Ketjen and KETJEN.

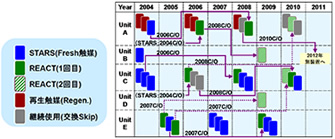

Cascade use of catalysts at refineries

- A large amount of cost reduction is possible by cascade use of catalysts between units or refineries.

- An example of cascade use is shown in the right figure. Circa 35% reduction of catalyst costs and a reduction of circa 60% of fresh catalysts are achieved in this example.